TMC-FLX-system

The modular integrated solution

3 in 1

- Measure, evaluate and sort at the same time

- Can be integrated into all inspection machines

Universal

Contactless

- Non-contact measuring without damaging the glass containers

- No recalibration required over the product's entire lifetime

Low-maintenance

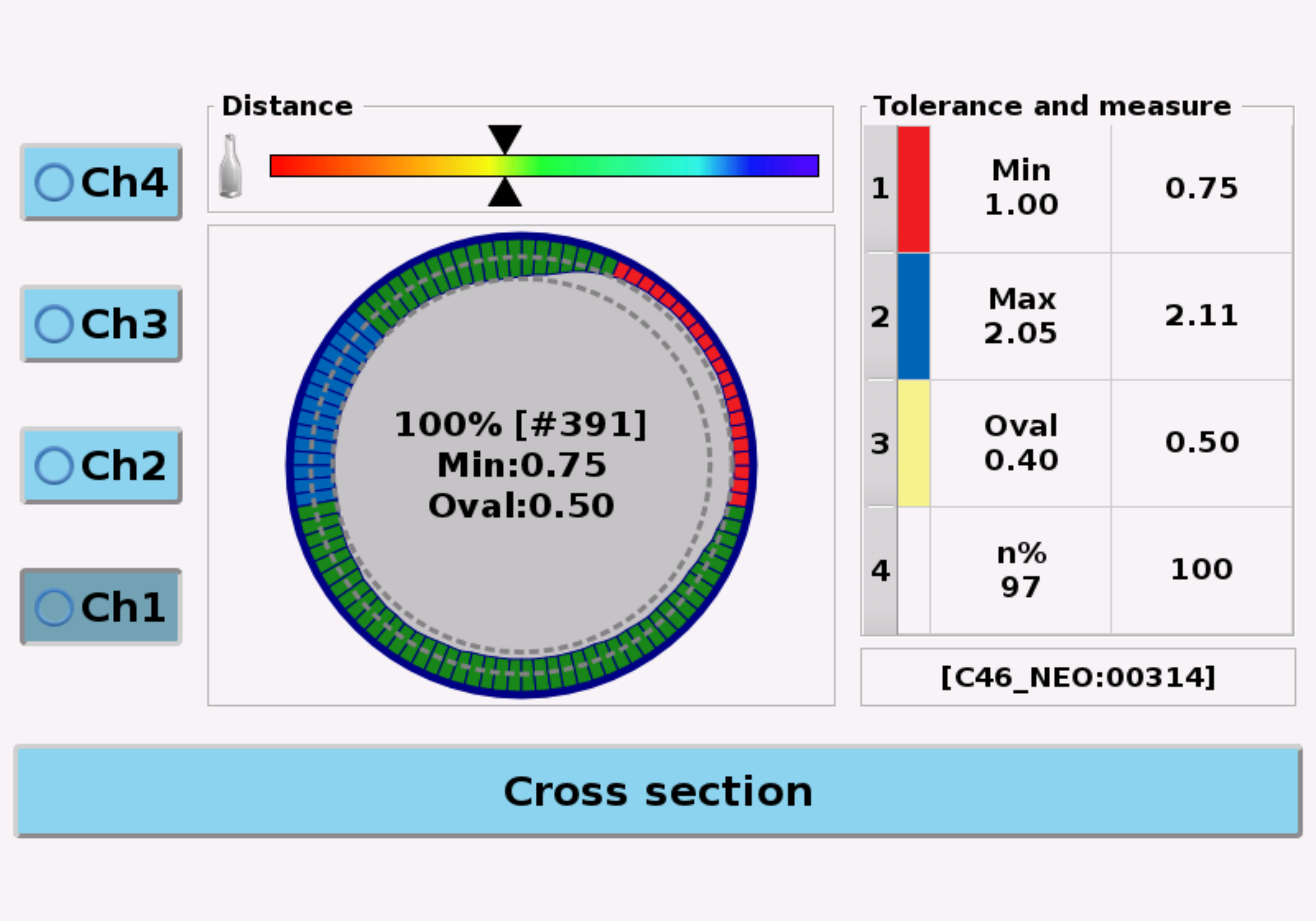

Non-contact measurement of glass containers

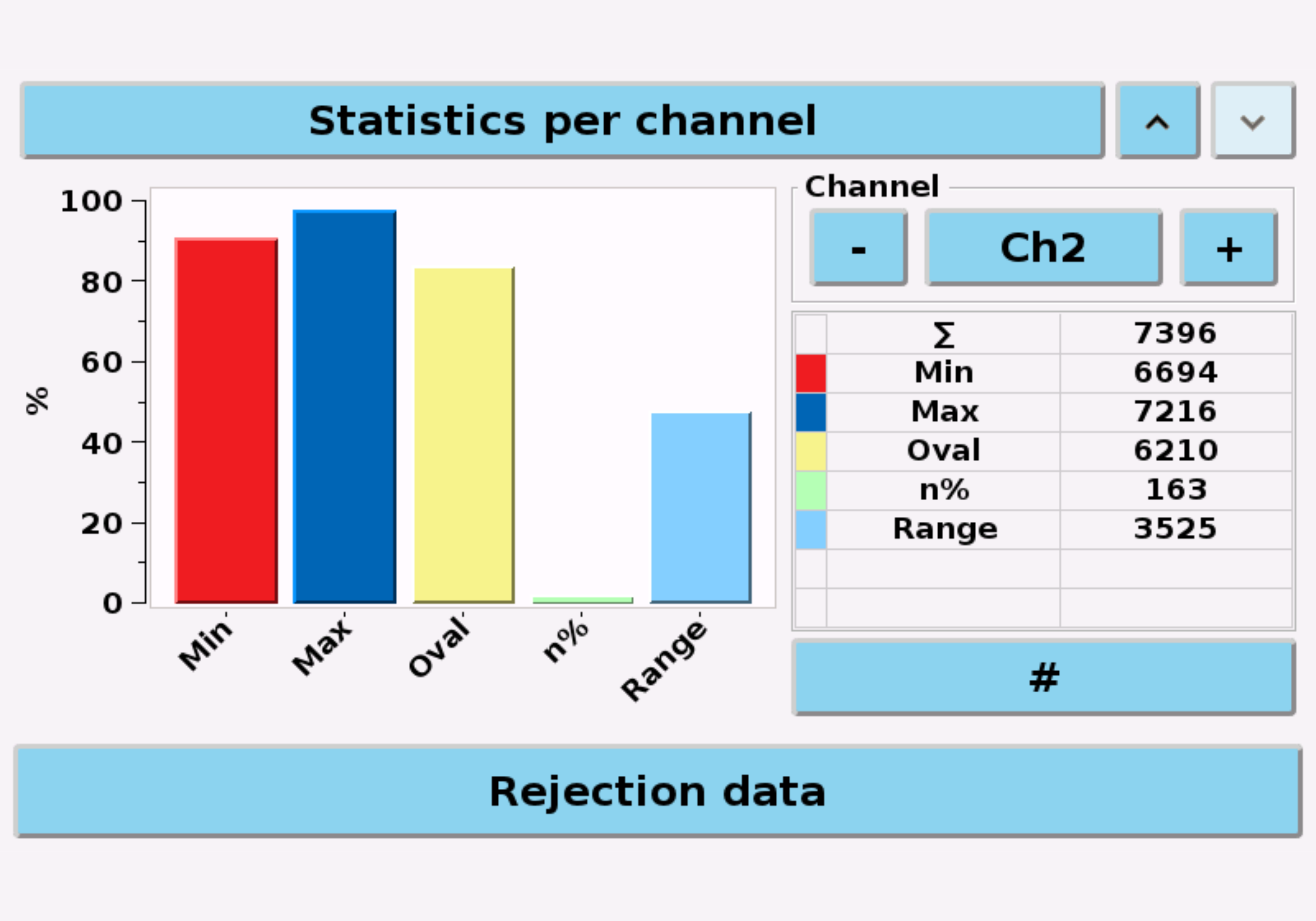

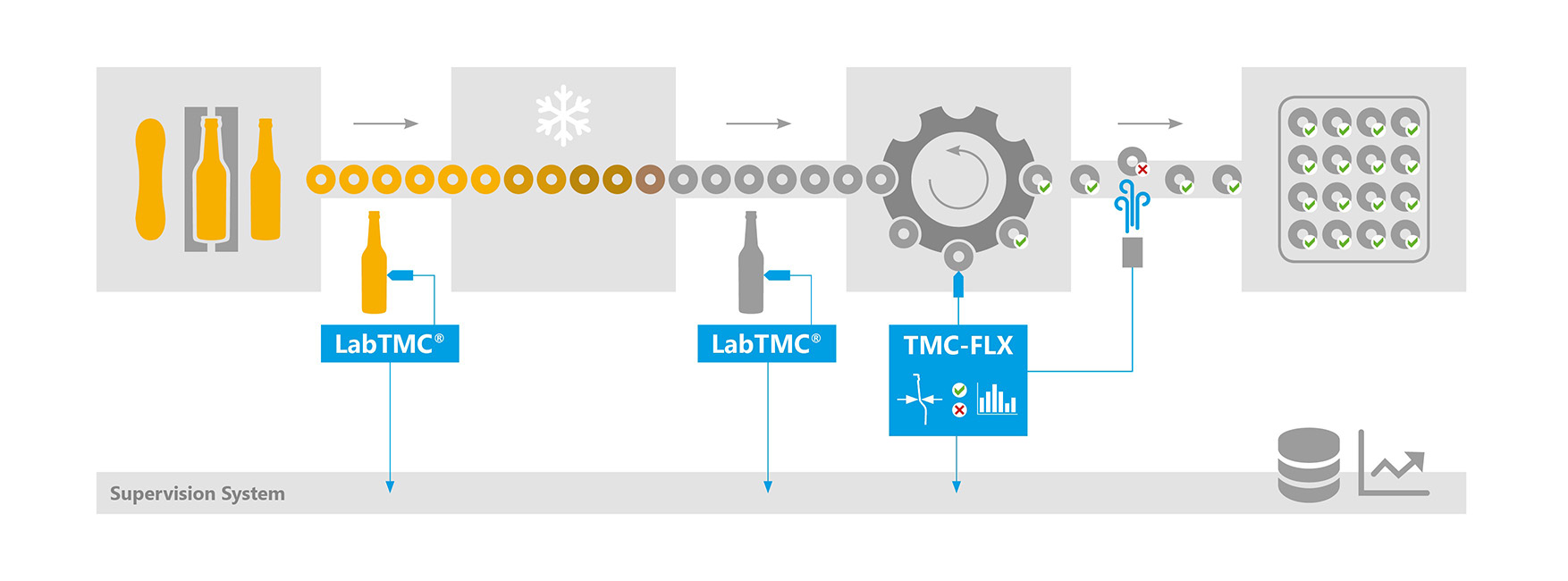

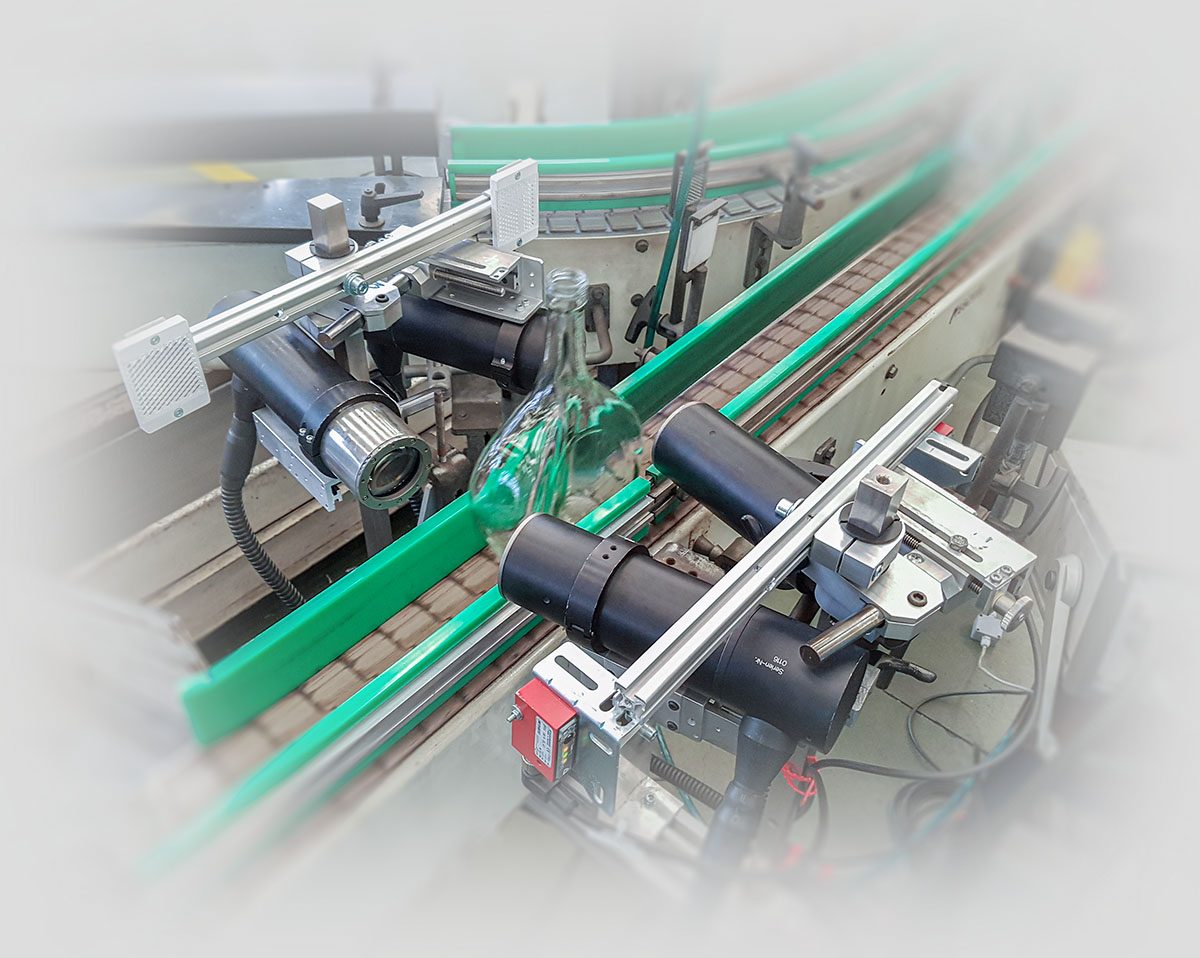

The TMC-FLX system measures the wall thickness distribution of containers at the cold end while they are rotating in the inspection machine. The measured values from the chromatic sensors are analysed in the base unit of the TMC-FLX system. This base unit then communicates the subsequent good/bad decision to the inspection machine and any defective bottles are sorted.

In addition, it is possible to couple the TMC-FLX system to a supervision system. The measurement data can be linked to mould numbers and therefore used to optimise processes. Spot checking the wall thickness on the production line is also necessary for process and quality controls.

The LabTMC® is suitable for this purpose and can be used at the hot or cold ends for offline wall thickness measurement. The convenient LabTMC® is ready for immediate use, meaning that bottles removed during production can be measured straight away.

Offline thickness measurement with the LabTMC

Our compact measuring device can be used for quick and accurate quality control in laboratories or for sampling inspections at the hot or cold ends in manufacturing.

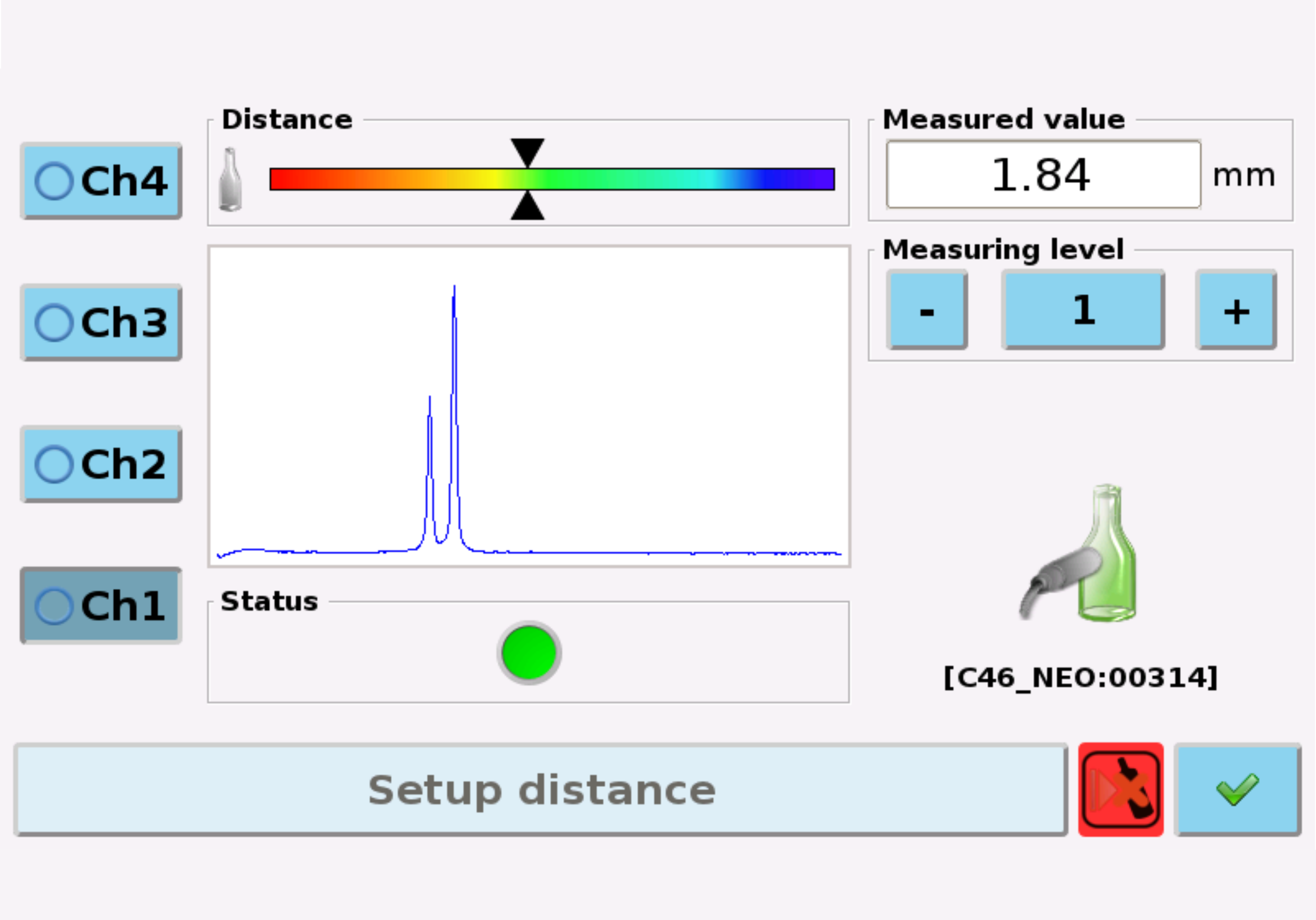

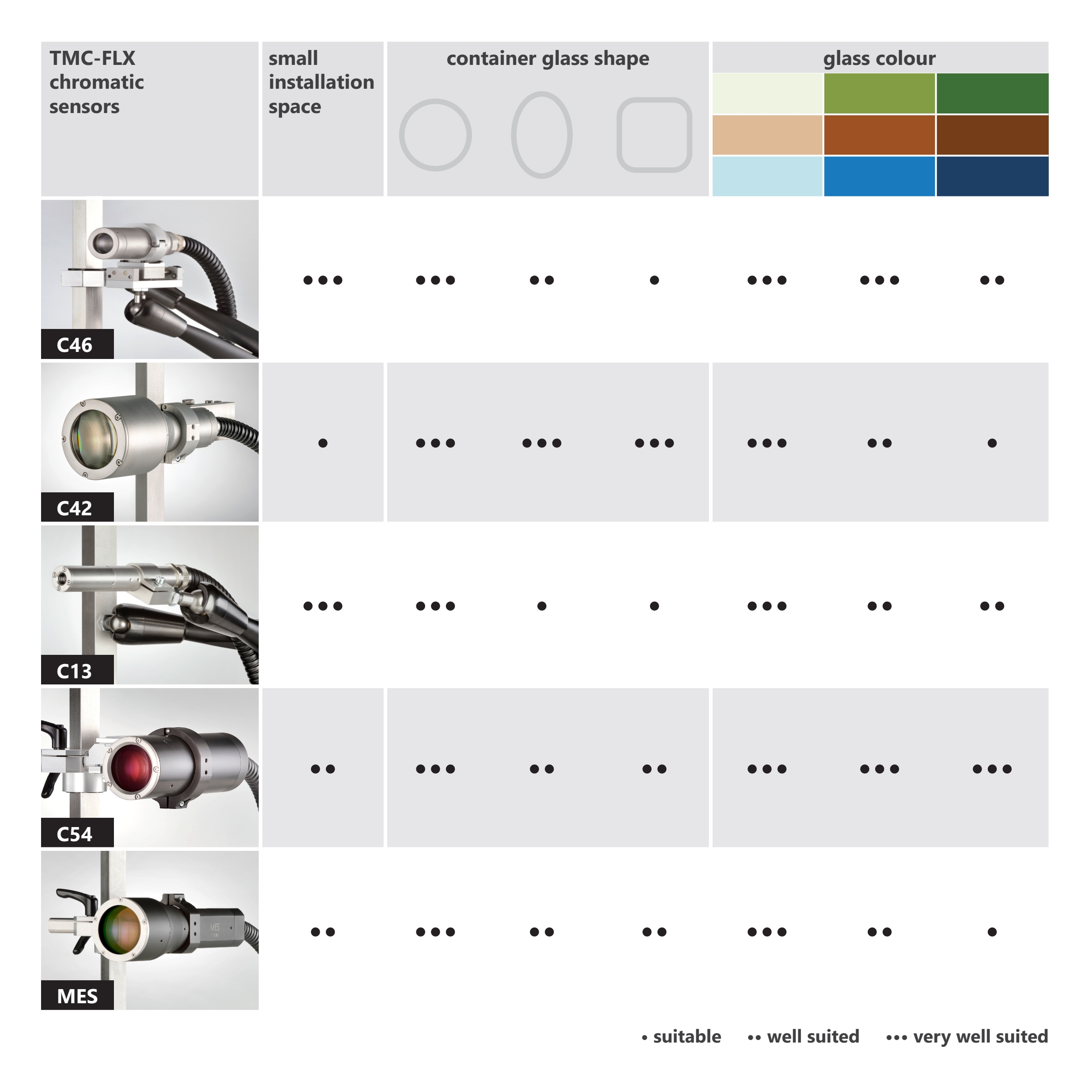

The sensors

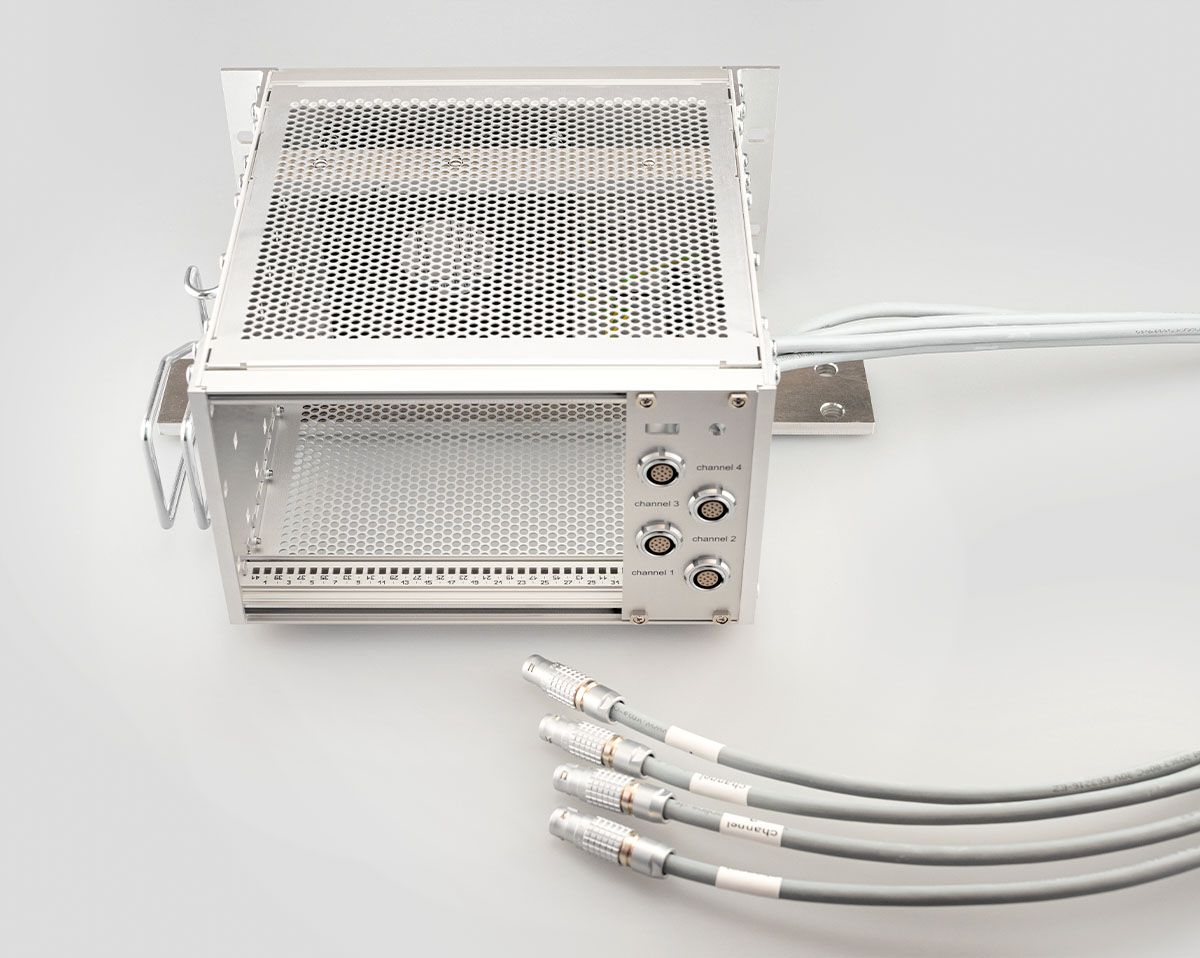

The TMC-FLX system has a modular structure. This means that all of our chromatic sensors can be used in combination with the base unit. A total of up to four sensors can be connected to the base unit.

Our all-rounder

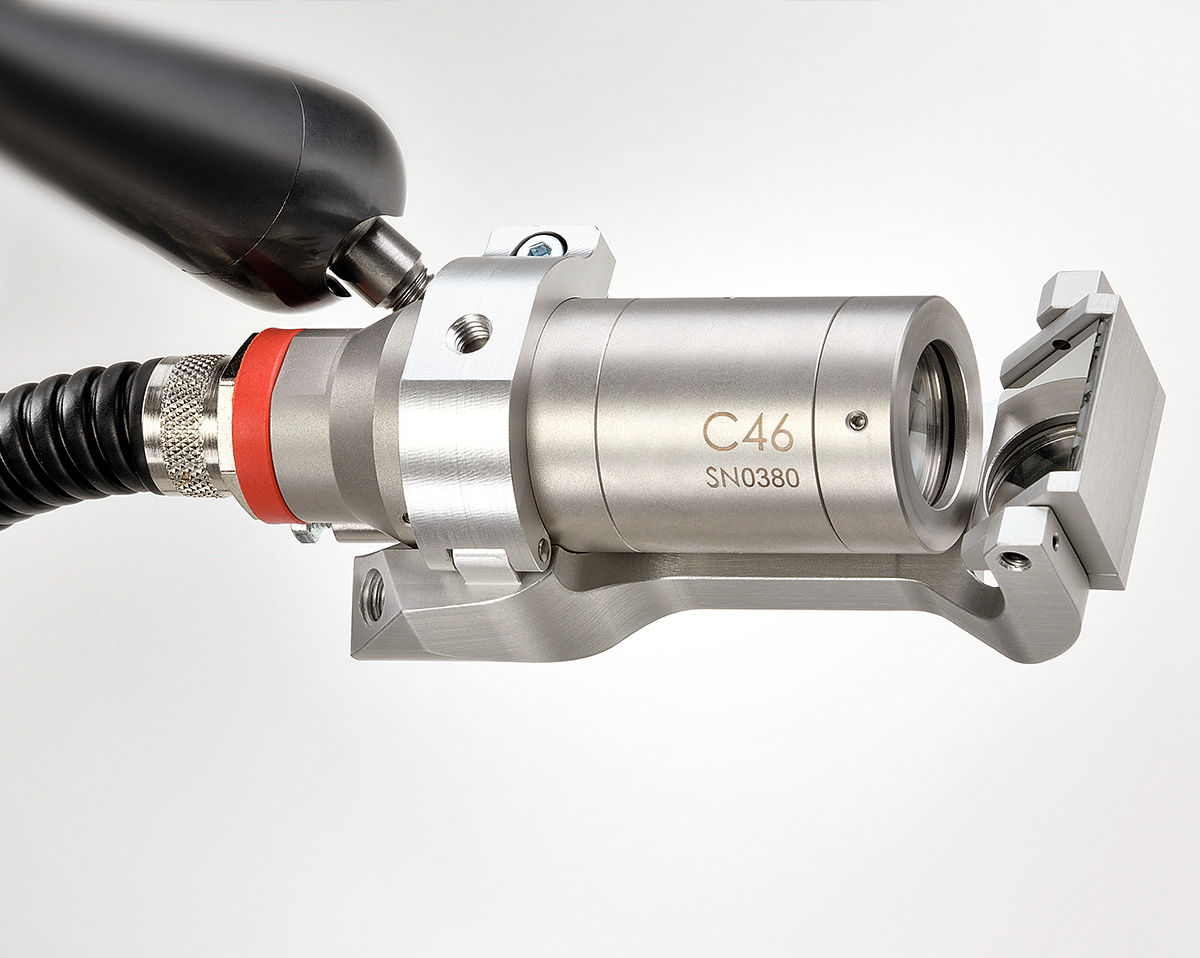

C46

- Suitable for (almost) all measuring tasks

- Compact and robust

- For use on an articulated arm

Our specialists

C42

-

For out-of-round and rectangular containers

C13

-

For very small containers

C54

-

For very dark containers

Our multi-level sensor

MES

- Four measuring points in a single sensor

- Large measuring field with high precision

- For non-stationary, thin areas

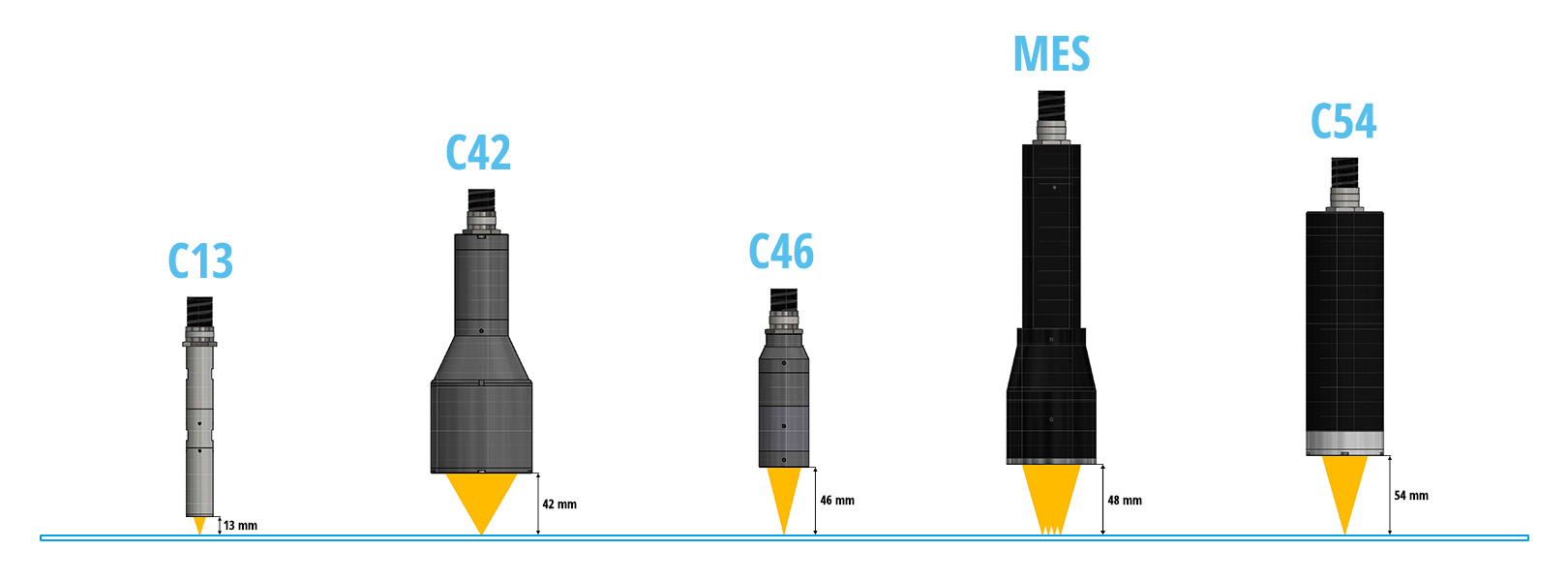

Overview of sensors with typical working distances

TMC-FLX – a comparison of chromatic sensors

Technical data

You can find an overview of our sensors with all specifications in our product catalogue.

We help you to find the right sensor

Accessories and areas of application for the TMC-FLX system

MCB2

Bridging technology between the TMC-FLX system and the TMC15-B, TMC28-B and TMC-B4 predecessor base units.

TMC-FLX EXT

Enables the TMC-FLX system to be fully integrated into the inspection machine – for greater protection and flexibility, as well as reduced repairs to the optical connections.

Conveyor measurement

The TMC-FLX system can also be fitted to a conveyor belt for container glass that is very out-of-round.

External monitor

For easier operation and a larger display.

MTA

Enables the TMC-FLX system to be connected to a supervision system. The collected measurement data can be linked to mould numbers and therefore used to optimise processes.

TMC-FLX-C46-BTMA

Base mirror for the TMC-FLX-C46 sensor to directly and reliably monitor the wall thickness in the base region.