Solutions that we have already developed for our customers

Glass tubing

Offline wall thickness measurement, diameter determination and sorting

Irrespective of when wall thickness measurement and diameter determination are performed during the manufacturing process, the measurements taken of glass tubing must be reliable – regardless of whether measuring a few millimetres or several centimetres in diameter combined with varying wall thickness.

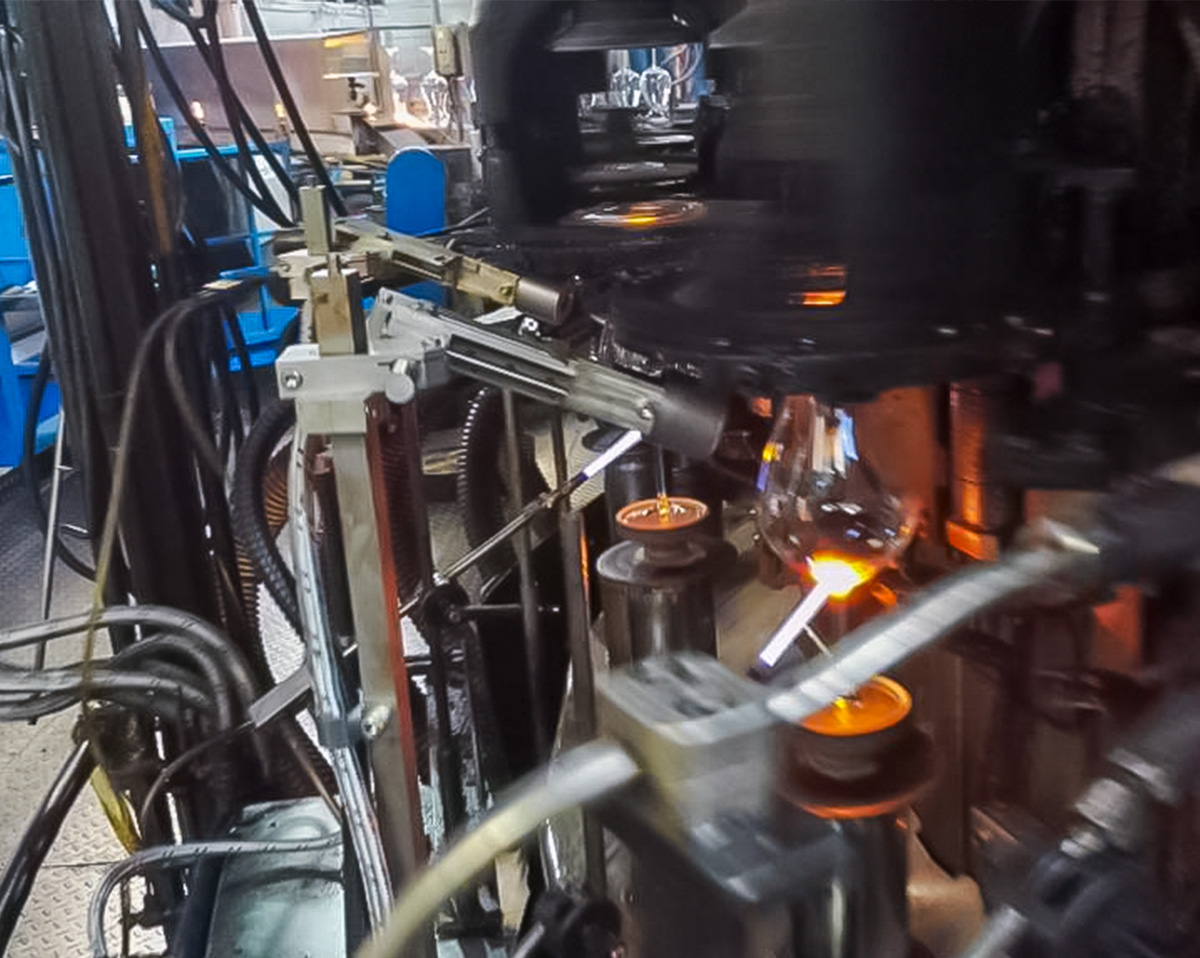

Tableware

Online measurement of wall thickness and glass distribution

One way in which tableware is produced is by using rotary blowing machines (RBM). When developing the measuring technology for online wall thickness measurement, consideration had to be given to the particular way in which this manufacturing process works and the prevailing ambient conditions. For instance, additional cooling of the measuring head is required. Also, the measuring head has to follow the continuous rotary movement of the RBM for thickness measurement.

The measuring technology developed by VMA for taking online wall thickness measurements of tableware supports the process controls at the hot end.

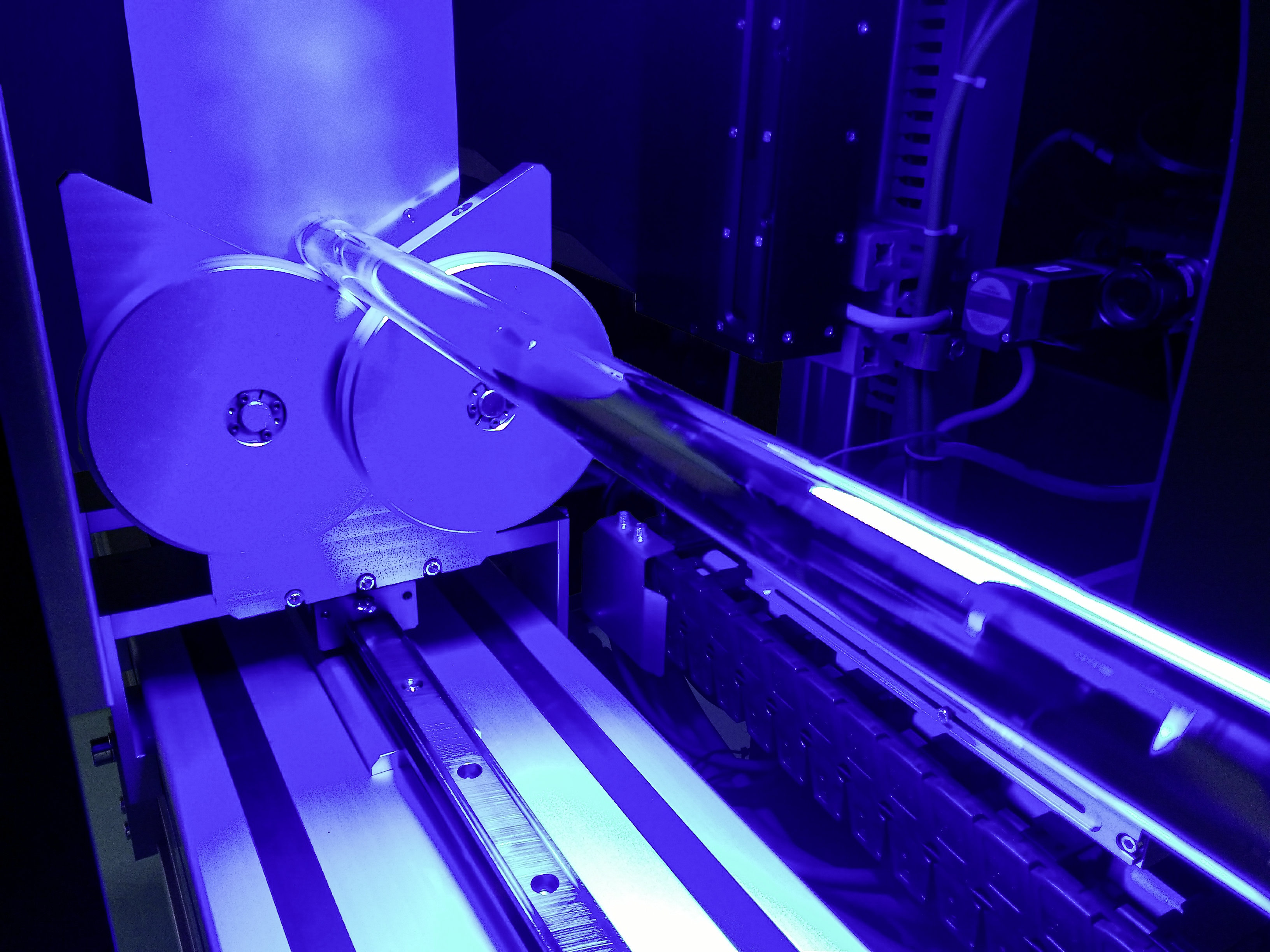

Preform (for glass fibre)

Offline Geometry Measurement And Defect Detection

The glass fiber is drawn from the preform. The preform consists of a core rod surrounded by a cladding tube. Since the glass fiber has the same properties as the preform, but is many times more filigree, geometry measurement and defect detection are essential for quality control already at the preform stage.

We offer fully automated inspection of the preform. This includes the determination of the diameter and the core-cladding concentricity (CCC), which indicates whether the core rod is concentric in the cladding tube.

C46x80: very thick glass/ varying distances

Online/ Offline thickness and distance measurement

The C46x80 sensor can measure glass thickness up to 80 mm. It is also capable of measuring strongly varying distances in a range of 54 mm in combination with a very compact design (Ø34 mm). Due to its unique characteristics, it enables various applications, e.g., flat glass, rods, tubes, lenses and multi-pane insulating glass, which requires a high operating range. Not only glass, but also other transparent materials such as PMMA or Polycarbonate are measurable using C46x80.

It can be used as a portable stand-alone device or as a part of a VMA four-channel base unit. The sensor operates non-destructive and features high accuracy as well as reliable precision – especially compared to magnetic or mechanic devices. In order to reduce time and effort, no recalibration is required over the sensor's entire lifetime. Its probe is designed for rugged industrial environments, making it suitable for production lines.