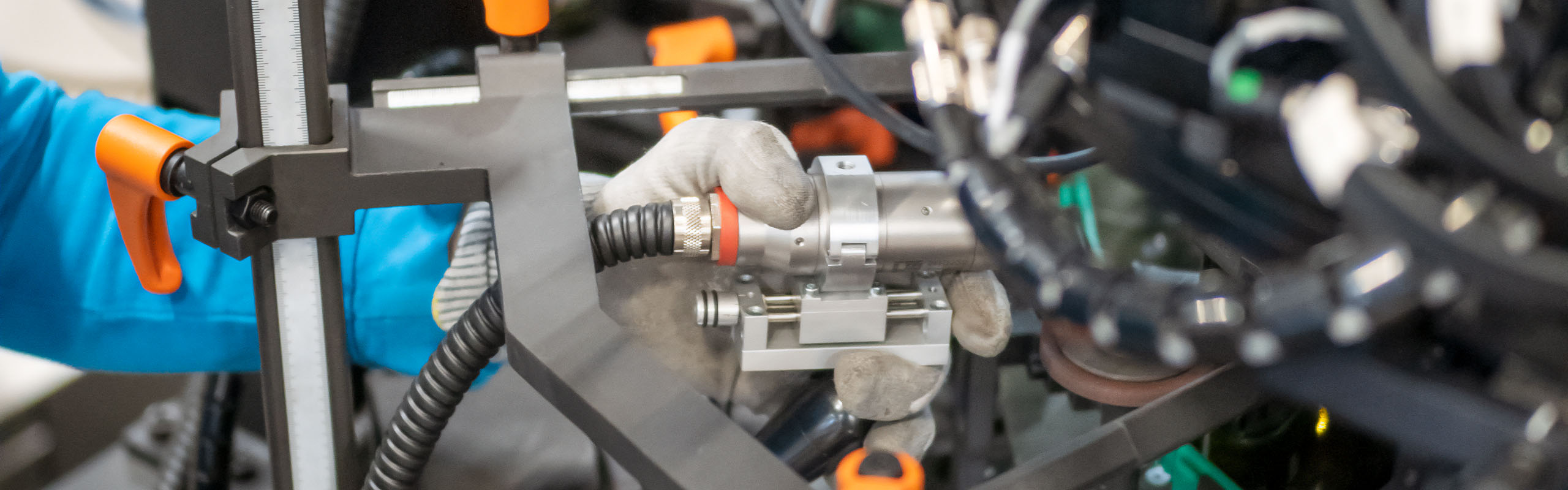

Installation

Our engineers handle assembly, adjustment, electrical commissioning and software adjustments at your premises, meaning that the VMA measuring technology is quickly ready for operation.

Training

We can train your staff in how to use VMA measuring technology independently so that they can operate the equipment quickly and effectively. In the course of this training, our engineers and technicians share their knowledge directly at the measuring system or sample object with your employees.

On-site and remote maintenance

It is important to regularly maintain VMA measuring technology to ensure that it has a long service life. We will gladly come to you to perform servicing or we can provide diagnostics and support with our remote maintenance service.

Repairs

You can send us defective components and sensor systems for repairs. We carefully analyse the error pattern and quickly rectify the problem so that you can reliably use VMA measuring technology again with full functionality.

On-site troubleshooting

In the event of acute or complicated problems that cannot be rectified by remote maintenance, we will come to you at your plant. We will analyse together the error pattern in advance and then make sure that we are able to quickly resolve the problem on-site.

Delivery of spare parts

The provision of spare parts ensures that our customers can reliably use VMA measuring technology for even longer. We therefore deliver the right spare part exactly when you need it.

Test measurements

If you would like to see how our measuring technology performs, you are welcome to send us glass samples for performing thickness measurements on.

Renting sensor systems

We also offer the option of renting our VMA measuring technology. This is available for a range of scenarios, including repairs, test measurements and for safeguarding your production facility during production peaks.

Consulting

With our extensive technical knowledge, we are ready to help and can devise solutions for your specific problem.